Tech Talk: Indicating the Health of your Brakes

Local outfit SHINVENGO offers brake wear indication systems that are easily retrofit to your vehicle, offering a convenient way to assess the remaining life span of your brake pads and linings.

Brake failure (or just the possibility of it) is costly and time consuming for car manufacturer. According to National Highway Traffic Safety Administration (NHTSA) (2020), General Motors is recalling an additional 14 620 trucks and SUVs because their brakes may suddenly become difficult to use. In June 2022, Mercedes-Benz recalled nearly one million older vehicles worldwide because of a problem that could cause a potential problem with the braking system.

There are vehicle owners out there who don’t consider brake maintenance a priority until something goes wrong. In most vehicles, the front two wheels have a braking apparatus that depends on what are known as rotors: metallic discs found behind each wheel. Above each of there is a clamp-like device called the calliper. When you hit your brake pedal, the callipers start to close, squeezing the disk from both sides. This action produces friction, which cause the wheels to spin slower until they come to a complete stop. Brake pads are the removable surfaces that callipers use to make contact with the rotors during this process.

"But when is the right time to replace your brake pads?"

These brake pads won’t last forever. The friction will inevitably wear the brake pads down over time. Let the brake pads get too thin, and your brakes won’t work as effectively as they should. For safety’s sake, it’s imperative that you get new brake pads installed at the first sign of trouble.

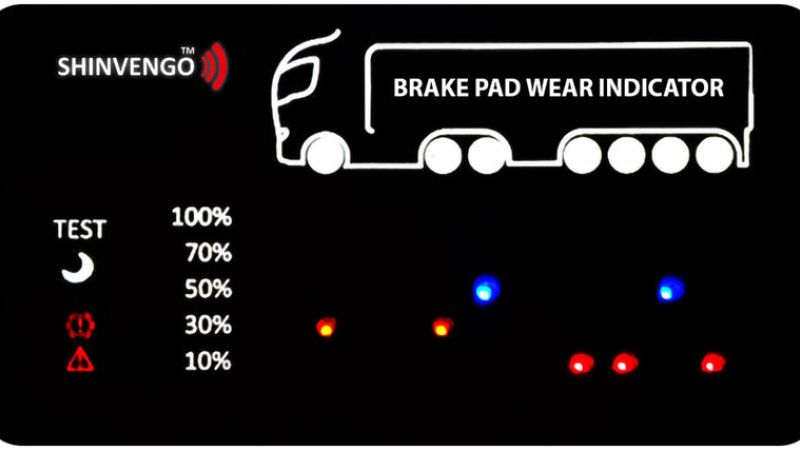

The presented invention is a brake pad wear indicator, which is a smart indication system for vehicle brake pads or brake shoes. SHINVENGO Brake Pad Wear Indicator provides a simple solution, replacing manual checks, saving you and your drivers time, and is thus reducing delays of deliveries. Using this system’s indicators of accidents caused by poor brake performance can be prevented by scheduling on-time maintenance.

The key features of this brake pad wear Indicator include:

- Both drum and disk brakes can be retrofit with the system

- Alerts to the driver when brake pad wear reaches a critical point

- Reduces additional repair costs caused by disc or drum damage

- Avoids time spent performing monotonous, time-consuming manual checks

- Using full service life, lowers maintenance costs

- Easy planning of maintenance periods

- Reduces risk and costs related to potential accidents caused by poor brake performance

Easy Installation, Effective Functions

The electronic control unit extracts the wear and thickness of the friction material of the brake pad or brake shoes from the sensor, and the wear level provided by the display is divided into different level. Each brake pad equipped with a sensor sends an alert to the smart board. The driver is alerted via a warning light on the smart board. As the brake pads on each axle wear differently, the system will indicate the thickness of the pad / shoe that is worn out more. Once one of the pads on one axel has reached the replacement level, both sides would then need to be replaced.

"And imagine, if this system prevents an accident, it has more than paid for itself."

According to Bernard Pang, Director, Sales & Marketing, SHINVENGO (M) Sdn Bhd, the system introduced by the company would be best suited for trailers and older trucks. “Modern trucks might already be equipped with such systems by the OEM. However, many trailers have multiple axles and most likely, these do not feature such systems.” He told Asian Trucker that the ease of installation and the resulting timesaving when checking the brakes of a trailer will be strong arguments for the addition of this system.

Currently looking for distributors in Malaysia, SHINVENGO is ready to take orders. Pang states that the installation is easy and the replacement of the sensors can be done by any qualified workshop personnel handling the servicing of commercial vehicles. “And imagine, if this system prevents an accident, it has more than paid for itself.”

Numbering the Problem

According to Department of Statistics Malaysia (2022), 4 539 and 4 634 deaths were recorded in 2021 and 2021 respectively. Selangor recorded the highest number of road accidents with 108 564 cases followed by Johor and W.P. Kuala Lumpur with 49 559 and 40 237 cases, respectively.

The number of road deaths in Malaysia this year is set to surpass that of the pandemic era, with the figure for January - September recording a 52 percent increase over last year. (FMT, 2022)

Malaysia has the third highest death toll from road accidents in Asia and Asean, behind Thailand and Vietnam. (Asia Insurance Review, 2019)

Between July 7 and Aug 17 this year alone, 10 fatal accidents involving heavy vehicles were reported. As reported, brake failure was cited as the main cause of the accidents concerned.