Six Prime Mover Brake Issues and How to Manage Them

Optimized uptime is essential for prime movers, as they keep the supply chain moving. However, when the brakes aren’t working correctly, drivers are in danger.

What problems should they be aware of?

1. Worn Pads

Brake pads only last so long before needing a replacement. Pressing them introduces friction, which make these components wear a little faster. Drivers may recognize worn pads once their braking efficiency is less effective than before, but knowing when to change them is essential.

Inspect the brake wear gauge to monitor the pads’ thickness. The owner’s manual should provide proper instructions on the recommended brake pad thickness. All eight should be above the 50% checkpoint, or it could be time to replace them.

2. Locking Brakes

Another issue with prime movers is locking. When the brakes lock up, friction compromises traction and complicates driving. Drivers should recognize this issue when the brake shoe becomes stuck after touching the pedal. An accompanying problem is the vehicle’s difficulty accelerating on any road.

You should check the anti-lock braking system when the brakes lock up. There could be underlying problems even if the warning light hasn’t appeared on the dashboard. For instance, the brakes could have rust buildup due to weather conditions. In this situation, you should use nitric or citric acid to remove rust from the surface.

3. Fading Brakes

Reduced efficiency could also mean the brakes are fading. Prime movers could have this problem because their load is too heavy or the system is too hot. Braking at high speeds could also be the culprit for this issue.

While some vehicle issues show signs, this one could be unexpected. Therefore, drivers need to be vigilant.

Fading can sometimes be temporary, so the fix includes pumping the brakes for shorter durations. If you press them for too long, the system could overheat. Persistent problems may necessitate changing the brake pads or rotors. Drivers should also check the brake fluid for contamination and follow manufacturer recommendations for changes.

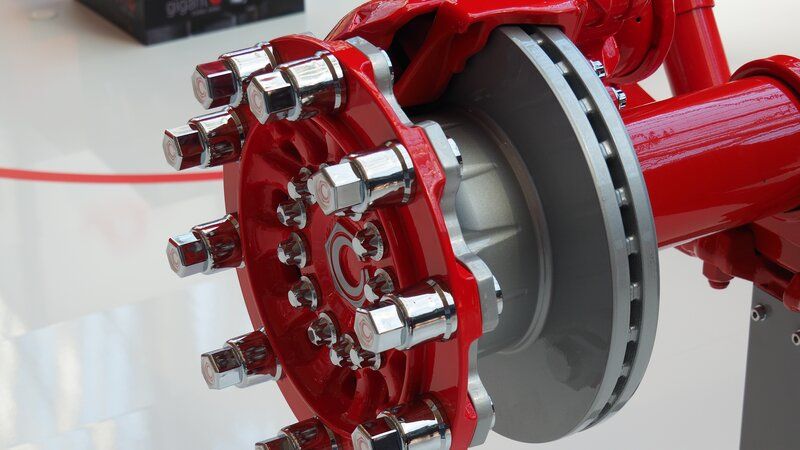

4. Rotor Damage

Squealing brakes could indicate worn brake pads, meaning your prime mover could also have rotor damage. Brake rotors wear over time, but some factors can accelerate the usage. Rust can build up and cause uneven wear and tear on the part, compromising performance and effectiveness. Drivers should spray the rotors with brake cleaner and clean them with a rag.

Prime movers’ brakes will also squeak when they accumulate dirt and mud. Thorough cleanings are necessary to mitigate the problem, so use efficient tools like pressure washers. Check the space between the rotors and pads — they could accumulate contaminants, too.

5. Vibrations

Vibrations in a prime mover are among the last things a driver wants to feel. When the vehicle starts shaking, it could originate from worn spark plugs, a bent axle or a flat tire. If the problem persists with the brakes, it could be due to overused brake pads or warped brake rotors. Heat, stress and other conditions can also cause this problem.

If your brakes are shaking, it may be time to change the rotors or pads. Otherwise, there could be a serious problem in other parts of the suspension.

For example, your prime mover’s tires could be misaligned. This shaking issue often arises when braking at high speeds or driving downhill. It may need a front-end realignment to ensure safety.

6. Air Issues

Air brakes are more reliable for prime movers, but they could still incur issues suddenly or over time. For instance, the airline could have difficulty supplying air and weaken the braking system due to a lack of pressure. Prime movers depend on pressurized air to make the brakes effective, so it could become dangerous for drivers.

Operators should conduct regular airline inspections to ensure the moving parts work correctly. When examining, they must also verify the air compressor functions without issues. You may hear a hissing sound, which indicates where the problem originates.

If there is a leak, remove the damaged section and replace it with a compatible new line. Clamps could temporarily mitigate the issue.

Ensuring the Prime Mover Is Ready for the Road

When drivers hit the road, their safety and efficiency are critical. Brake issues could occasionally cause problems, so knowing how to fix them is essential. Logistics professionals should train their employees to deal with these mechanical problems and understand why they occur. While regular maintenance is necessary, drivers should know what to do in a pinch.

Author Bio: Oscar Collins is an auto writer with over five years of experience in the industry. He has bylines at Carwash, Global Trade Mag and InAutomotive. Follow him on X @TModded for frequent updates on his work.